Product Introduction:

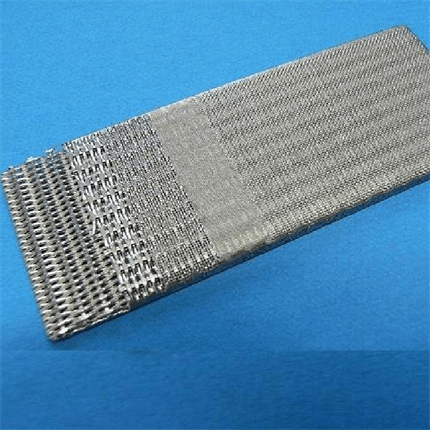

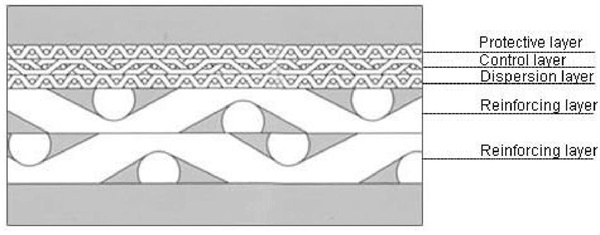

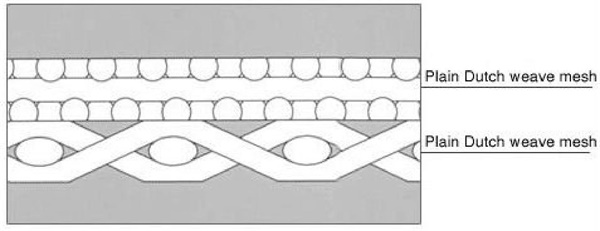

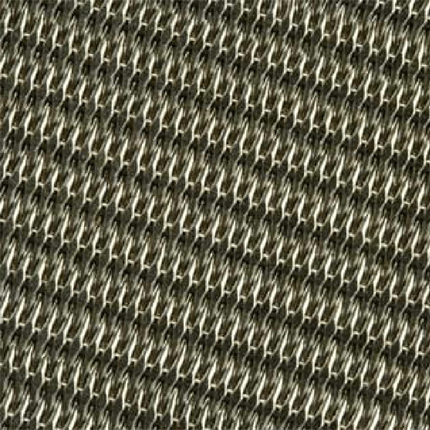

Standard sintered five-layer mesh consists of the protective layer, the filter layer, the dispersion layer, and two reinforcing layers. It provides excellent performance such as uniform and stable precision and high strength, so it is ideal filter medium for applications requiring high compressive strength and uniform filtering particle.

Thanks to its surface filtration construction and smooth aperture duct, it is good at backwashing and regeneration, therefore, it can be used for a long time, and is especially suitable for continuous and automatic operation, which exceeds any other kind of filter material.

Furthermore, this sintered mesh is easy to be formed, machined and welded. It can be produced into many kinds of shapes such as circular, cartridge, cone and pleats.

Product Features:

1.High strength and rigidity: extreme mechanical strength and pressure tolerance, can be machined, welded and assembled,

2.Uniform and stable precision: consistent filter property in various media, without apertures changing during operation.

3.Widely service environment: can be continuously in temperature ranging from -200℃ to 600℃ and filtering in acid and alkali conditions.

4.Cleanable: backwash easily, and reused with longer service span, and can be cleaned by means of ways, such as backstream, filtration liquid, ultrasonic, dissolution and baking.

Product Technical Parameters:

|

TYPE |

Nominal Micron um |

Working Micron um |

Air Permeability L/min*cm2*pa |

Bubble Point Pressure Pa |

|

SW1 |

1 |

6-7 |

|

5300-6000 |

|

SW2 |

2 |

8-9 |

(1-6)*10-4 |

4300-5000 |

|

SW5 |

5 |

11-13 |

(6-10)*10-4 |

3000-3700 |

|

SW10 |

10 |

16-18 |

(6-10)*10-4 |

2700-3300 |

|

SW15 |

15 |

24-26 |

(1-6)*10-3 |

2000-2600 |

|

SW20 |

20 |

28-32 |

(1-6)*10-3 |

1800-2300 |

|

SW25 |

25 |

34-36 |

(6-10)*10-3 |

1400-1900 |

|

SW30 |

30 |

40-45 |

(6-10)*10-3 |

1200-1700 |

|

SW40 |

40 |

50-55 |

(1-6)*10-2 |

1000-1500 |

|

SW50 |

50 |

71-80 |

(1-6)*10-2 |

900-1200 |

|

SW70 |

70 |

86-95 |

(6-10)*10-2 |

700-1100 |

|

SW100 |

100 |

110-120 |

≥5*10-2 |

650-1000 |

|

SW150 |

150 |

|

≥5*10-2 |

|

|

SW200 |

200 |

|

≥8*10-2 |

|

|

SW300 |

300 |

|

≥8*10-2 |

|

Note:

Standard size: 1000mm×500mm 1200mm×600mm 1000mm×1000mm

Standard thickness: 1.7mm

Standard material: 316L.Stainless steel like 304, 321 can be used either.

The parameter in the list is for your reference, the order is subject to the inspection.

Product Introduction:

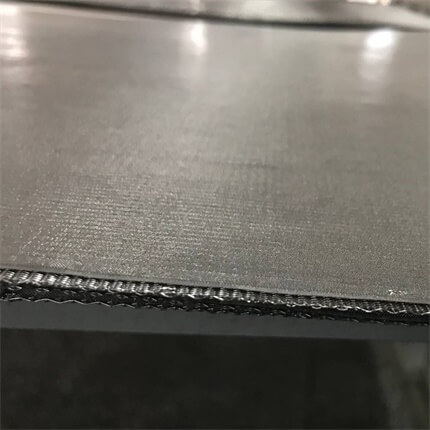

Sintered six-layer mesh is composed of six-layer stainless steel wire mesh, which is special canlendering and sintering in vacuum oven, to create a new filter material with high strength and rigidity. Its interlaced mesh forms a uniform and ideal filtration structure. As a new filter material, it has excellent performances such as high precision and strength, efficient flow restriction, mechanical and resistance to abrasion, heat and cold. It is mainly applied in pharmaceutical and food industry etc., especially in the three-in-one or two-in-one pharmaceutical equipment.

Product Features:

1.Add one layer wire mesh of 8 mesh or 12 mesh square wire mesh on original standard five-layer mesh, it has better strength and distributary performance;

2.High strength: high mechanical strength and compression strength;

3.High precision: 1~300um;

4.Heat resistance: continuous filtration -200℃ up to 650℃;

5.Clearance: with excellent surface filtering structure, easy to clean.

Product Specification:

1. Standard material: SUS304, SUS316L;

2. Standard specification: 500×1000×1.7mm

3. Filter rate: 1~300um;

The special size is object to the buyer’s requirement.

Product Introduction:

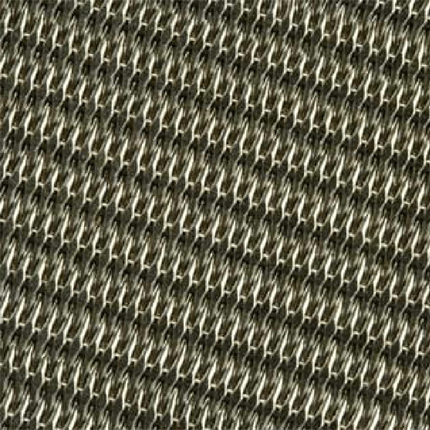

Multi-layer sintered woven mesh is composed of multi-layer stainless steel wire mesh, which is special canlendering and sintering in vacuum oven, to create a new filter material with high strength and rigidity. Its interlaced mesh forms a uniform and ideal filtration structure. It has excellent performance such as excellent filtration precision, filtration resistance, mechanical strength, wear resistance, heat resistance, cold resistance and processability, it is more ideal for the demand for pressure strength and filtration precision uniform. It is widely used in many industries such as the petrochemical, nuclear power, synthetic fiber, film, food, pharmaceutical, aerospace and environment protection industry.

Product applications:

1.Distribution and cooling material in high temperature;

2.Material used for gas distribution and fluidization bed;

3.Material requiring high precision, stable performance in high temperature;

4.High pressure backwashed oil filter;

Product Specifications:

1. Standard matetial:SUS316L, SUS304

2. Standard size: 1000mm×500mm 1200mm×600mm 1000mm×1000mm

3. Filtration rate: 2-300um;

4. Special sizes are available on request.

Application Projects:

1) Hydraulic oil & lubricant oil filtration in machinary industry;

2) All kinds of polymer filtration in chemical fiber film industry, filtration in high temperature and for corrosive liquid,material filtering, cleaning and drying in pharmacuetical industry;

3) Gas distribution in powder industry,fluidization in steel industry;

4) Buzzer for explosion proof electric apparatus;